WATER MANAGEMENT

Information

JULY 22, 2024

Daniel Chamorro

Urban network and hydraulic modeling analyst | Linkedin

Models.

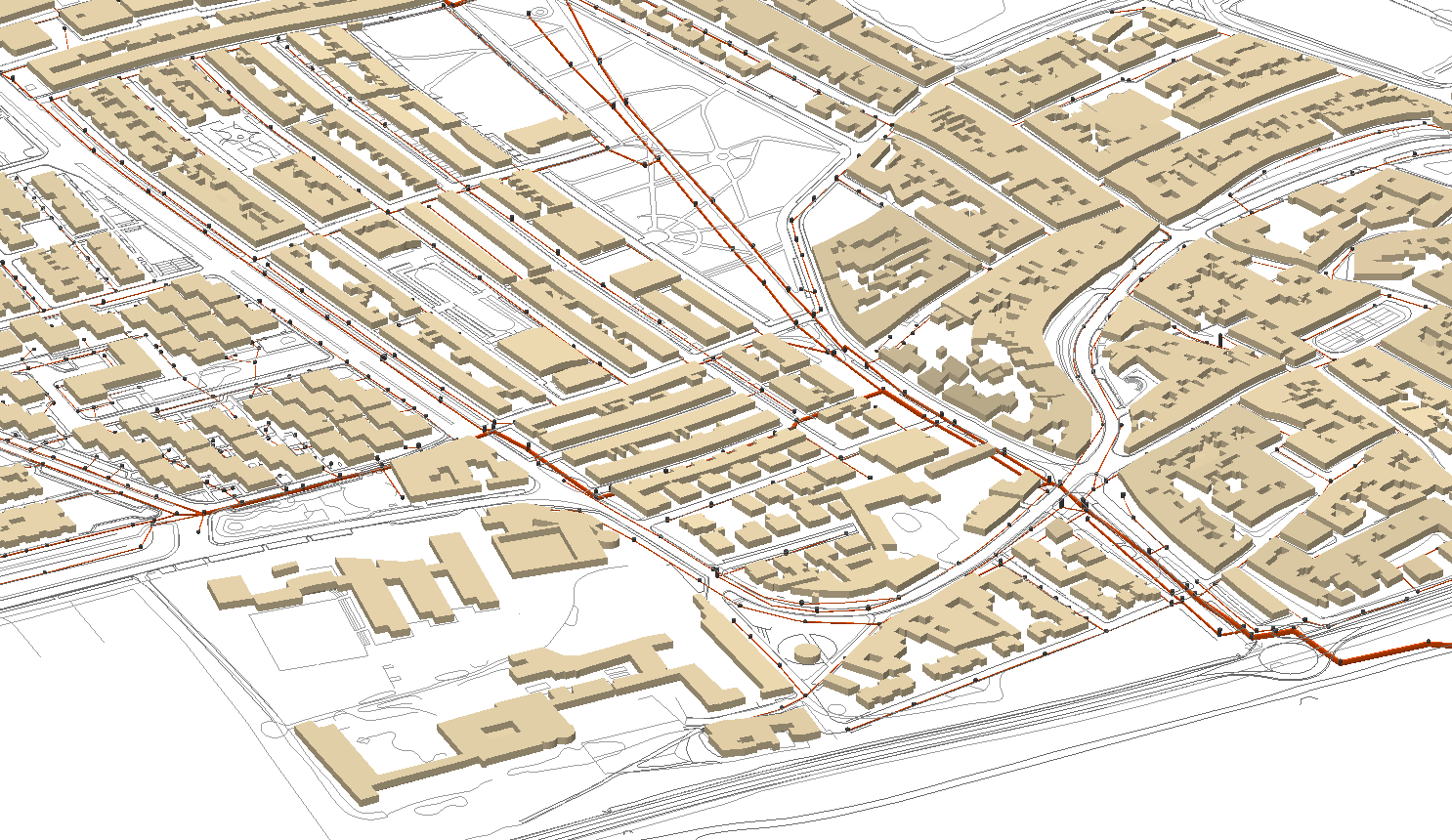

Compared to utility networks, sewer networks are usually the most neglected in terms of modeling. This is compounded by a greater complexity, both in terms of the amount of information involved and its typology. Manhole depths, projections, geometries, slopes, permeabilities, catch basins… are just some of the parameters that need to be validated.

The objective of this procedure is to reduce the time required for processing and correcting the previous information necessary for hydraulic modeling.

Before carrying out any hydraulic study, in this case the modeling of a sewer network, it is necessary to validate the cartographic information provided. The process of detecting, checking and correcting these errors can be laborious, significantly increasing the time required to complete the work, or leaving errors that will later manifest themselves in the modeling. The idea is to make all the necessary corrections before generating the hydraulic model, thus ensuring that it is not necessary to go back and verify the quality of the information provided.

If we consider that in a typical municipality of 10,000 inhabitants it is common to have more than 40 km of pipes and more than 1,500 manholes, the manual verification of at least 10 parameters per element means the verification of at least 15,500 data.

In this part we will focus only on the methodology used to validate the data from the information provided, basically based on the premise that the water flows by gravity to the point of discharge, without focusing on the topological and geometric analysis of the network, which are fundamental and must be carried out prior to this phase.

One solution could be to revise the longitudinal profiles of the sewer pipes street by street, manually identifying the sections with a slope opposite to that of the natural water flow. This method, although it may be feasible, is not feasible when analyzing the network of a complete municipality.

The geographic information system itself, from a small programming, allows to identify sections with negative slopes, to complete the depths of adjacent manholes, as well as to verify the logic in diameters, materials and sections of each existing element in the network.

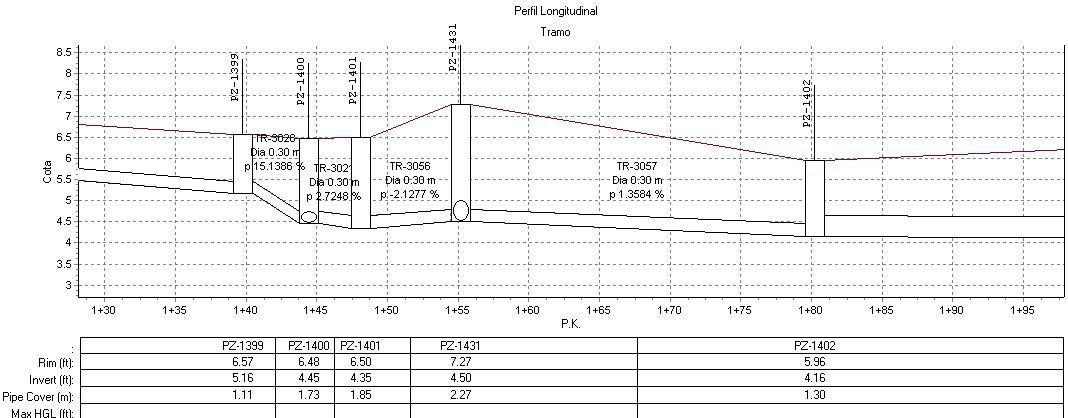

Longitudinal section profile of the sewage system

Three-dimensional view of the sewage network

This methodology requires the information to be exported to a calculation processor, from which, by means of dynamic tables and other logical processes, the typology of the manhole or node can be determined according to the number of outlets, inlets and associated depths, identifying the wells from which the water can no longer flow, i.e. sinkholes, which are usually associated with errors in the information provided.

On the piping side, it verifies that there are no inconsistencies between diameters, materials and shapes in pipes and manholes, detects small diameter connections to large collectors, the number of connections per well, sudden changes in diameter in the collectors, or verifies whether a network is truly separate or not, all through a methodology with a high degree of automation.

In the last phase, the heights and depths of the sections where we have detected failures are verified and corrected through longitudinal profiles, which allow us to ensure the continuity of flow in collector sections with a greater lack of information and in sections of greater complexity where there are a large number of wells and connections.

In short, the aim of this procedure is to reduce the time needed to process and correct the previous information required for hydraulic modeling, thus providing a solid basis for the subsequent development of the model. In addition to reducing the time required to correct errors, it facilitates a dynamic workflow that allows changes or additions to the model to be made in a more efficient manner.

.