EPCM – ArcelorMittal

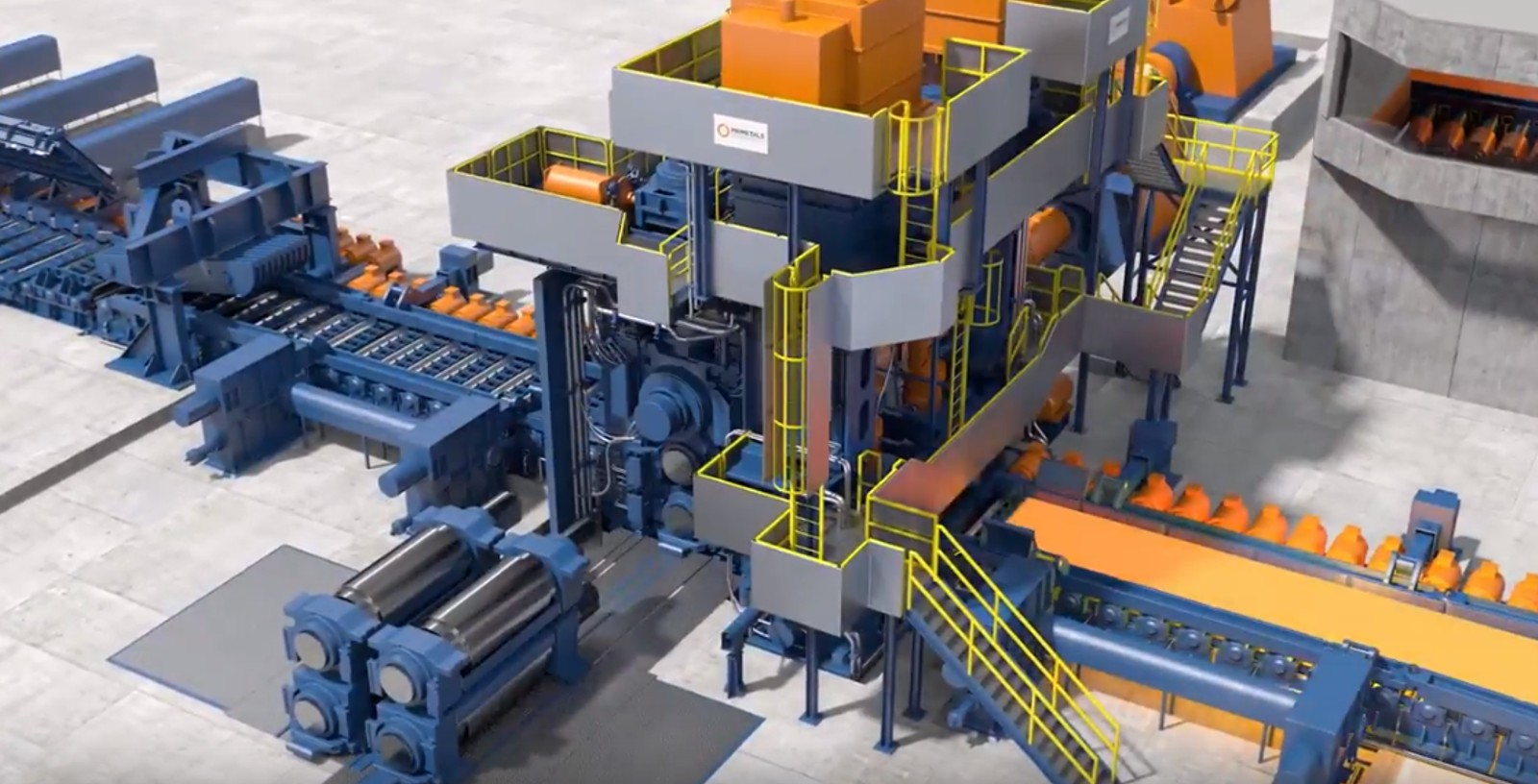

Steel Hot Strip Mill Plant in Lázaro Cárdenas

Mexico

ArcelorMittal undertook in 2017 a series of improvement and modernization projects for its steel production plant in the municipality of Lázaro Cárdenas (Michoacán), in Mexico. Among them, the construction of a new steel hot strip mill, with an initial capacity of 2.5 Mt/year that will reach up to 4 Mt/year in a second phase.

Part of the new plant is located in the old rolling facilities (brownfield), while the rest will occupy an area of the plot without previous use (greenfield).

IDOM is carrying out support services for the ArcelorMittal Project Team, acting as Owner’s Engineer for the EPC portion and as EPCM for the Balance of Plant (BoP) portion, with a multidisciplinary team that covers all aspects of the project, among which are:

- Technical leadership by disciplines

- Engineering coordination

- Purchase management

- Contract management and supplier supervision

- Cost & Schedule control

- Documentation control

- Logistics & Warehouses

- Quality control supervision

- Construction management

- Start-up consulting

The scope of our services also includes the detailed engineering of the BoP (utilities and off-sites), as well as the coordination of the engineering of the main contractor with the rest of the plant.

One of the main challenges of this project is the achievement of the highly demanding deadline, 30 months from the contract signature until the production of the first steel coil.

CLIENT:

ArcelorMittal

SCOPE:

Detailed Engineering - BoP

EPCM - BoP

Owner's Engineering - EPC