SURGICAL ULTRASONIC BONE-CUTTING DEVICE

Spain

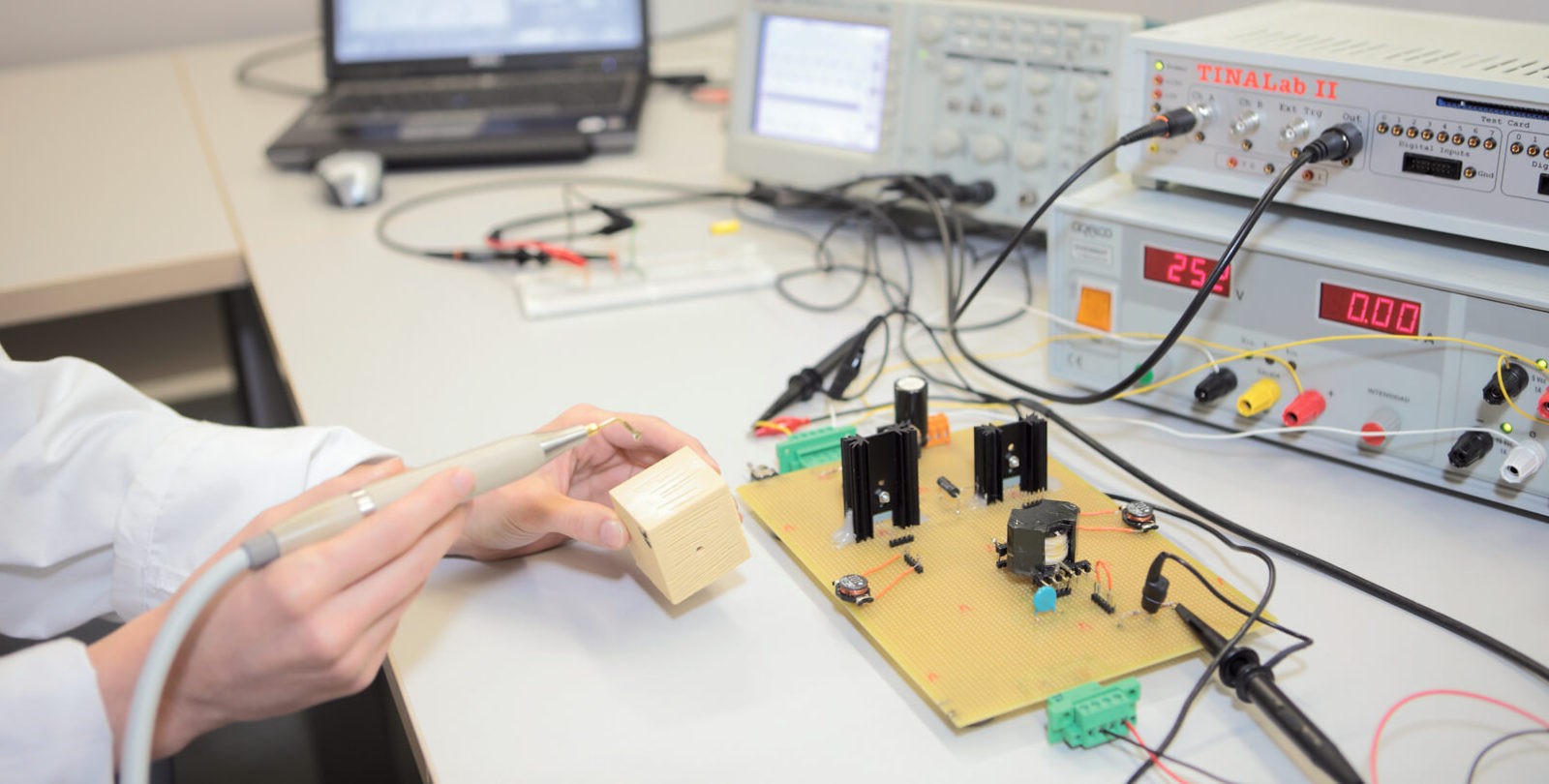

In the last couple of decades, ultrasonic cutting devices have been established in the surgery field as an alternative to conventional methods. These devices, powered by piezoelectric actuators, allow for precision bone cutting, at ultrasonic frequencies, with little damage to soft and neurovascular tissues. The project consists of the design and manufacturing of an ultrasonic bone cutting device including the development of novel analytical and multiphysics methodologies for its optimization.

Más información

The piezoelectric scalpel allows cutting into the bone without damage to soft tissue. It is used in fields such as dentistry, maxillofacial surgery, orthopaedics, neurosurgery, and so on.

This instrument replaces the tools powered by micro motors, that have limited access to complicated areas and can damage soft tissue. Micro motors generate a high level of mechanical energy, which is converted into heat through friction, and can damage tissue near the bone. As such, they require an irrigation cooling system; which can be difficult to integrate into these designs.

The piezoelectric scalpel provides greater precision, making it cleaner in the tool-bone interface, compared to traditional scalpels. The heat produced, is lower than conventional tools and the risk of contamination during surgical procedures is lessened.

Working for the BTI Biotechnology Institute, IDOM has redesigned the blade, focusing on the study and design optimization for the user, in order to improve performance. Compatibility with other units being manufactured is also a consideration.

Precision Instruments : Product Design & Development

CLIENT:

BTI – Biotechnology Institute

SCOPE:

Design